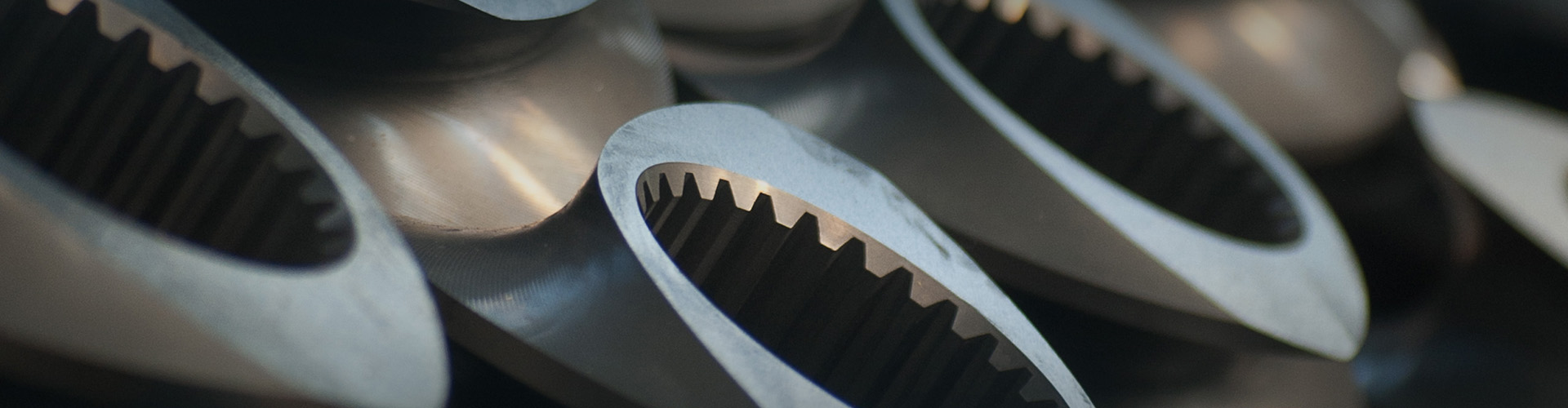

screw elements

A twin screw extruder is a machine consisting of two intermeshing, co-rotating screws mounted on splined shafts in a closed barrel. The screws are tight and self-wiping, which eliminates stagnant zones over the entire length of the process section. This results in high efficiency and perfect self-cleaning. Twin screw extruders can be used in polymer, chemical, and food industries.

When needed, various screw segments with different processing functions, such as conveying, kneading, mixing, shearing, and compression, can be configured to meet the processing requirements of a specific product.

Makes: Krauss Maffei, Coperion, Toshiba, JSW, SM, Leistritz

Co-rotating twin-screw extruders are extensively used for the preparation, compounding, mixing, and processing of plastics, but also in other industry branches, such as in rubber and food processing, and increasingly in the pharmaceutical industry too. Co-rotating twin-screw machines usually have modular configurations and are thus quite flexible for adapting to changing tasks and material properties. Well-founded knowledge of machines, processes, and material behavior is required in order to design and operate twin-screw extruders for economically successful operations.

Small screw elements and segmented barrels for twin screw extruders, laboratory, pilot and production lines for plastic processing industry.

Hemu Precision supplies shafts and screw elements for co-rotating twin screw systems. The shafts are manufactured by milling and are designed according to the customer’s drawings. Customer drawings are also the basis for the screw elements.

While standard elements as well as shafts are manufactured in nitrided design, the screw elements can also be manufactured in wear-protected design to a large extent. A large proportion of these are manufactured with the so-called PM-HIP wear protection design.

Feedscrews and extrusion screw segments are used for transporting, mixing or kneading powders and dry bulk materials. Twin-screw extruders are used for processing Powder Coatings, Thermoplastics, Biopolymers, Medical Plastics, Chemicals, Food and Pharmaceuticals.

Our range of feedscrews includes single-start and multi-start extrusion screw elements in all geometries. We manufacture your individual feedscrew elements with a diameter of 10 mm to 280 mm with a keyway, a hexagon bore, a 24 tooth spline or your very own individual inner design – just send us your technical drawing.

Extruder mixing elements, feedscrew kneaders, conveying elements, reverse elements and transition elements from single flight to twin flight – all customized to your requirements and including all required surface treatments.

Every feedscrew manufacturer generally focuses on a specific portfolio of standard feedscrew elements for specific machine models. We however can virtually manufacture any type of feedscrew element according to any norm, with any pitch and out of any material.