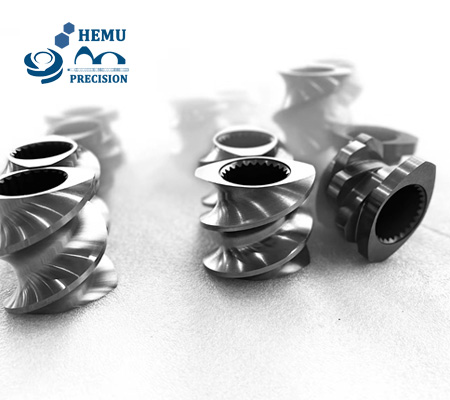

Hemu Precision is specialized in the twin screw extrusion technology. The co-rotating extrusion units are used for compounding materials where thorough mixing is important. Co-rotating twin-screw extruders usually have modular configurations, which makes the equipment quite flexible for adapting to changing applications and material properties.

Modular barrels and screws can be assembled in any combination to provide plasticizing raw material feeding, ventilation, or gas extraction. The co-rotating intermeshing screws are arranged in parallel and are self-cleaning. Screw geometry can be adapted to individual applications. The co-rotating twin-screw compounding lines are widely used for the production of plastics compounding, powder coatings, food cereals, snacks, aquatic feed and pet food.

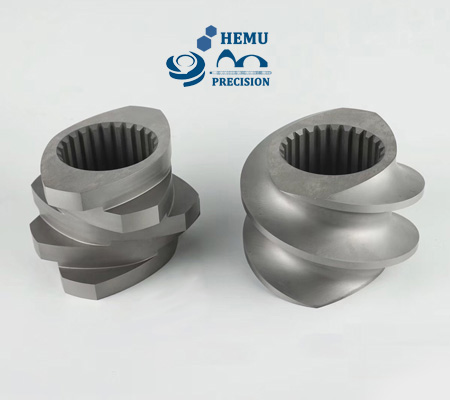

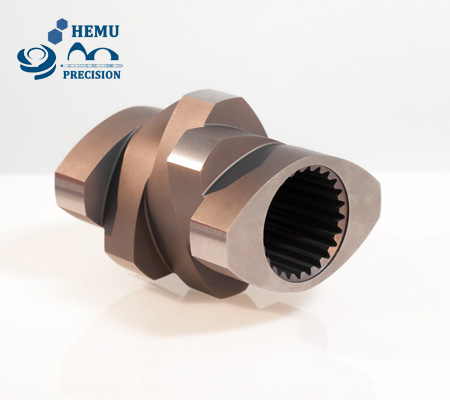

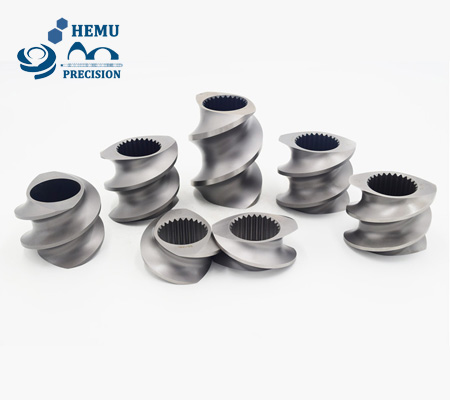

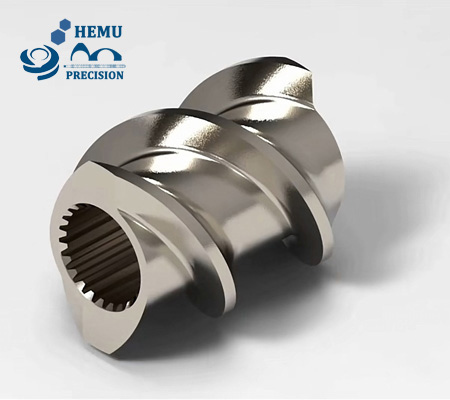

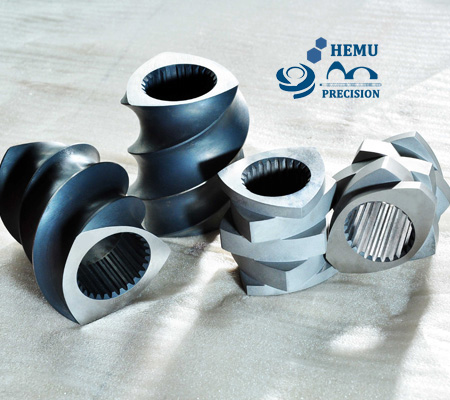

All types of screw elements include kneading blocks, mixing elements and conveying elements.

twin screw parts, twin screw extruder wear parts, segmented screws, self-wiping screw design and modular barrels for high torque twin screw extruders

We manufacture OEM quality extrusion wear and replacement parts for the the leading OEM manufactures in the twin screw extrusion compounding industry.

Screw elements, screw shafts, tips and couplings, barrels and liners for the twin screw extruders in the operation of compounding, filling, reinforcement, degradiation, coloration, grafting, crosslinking, etc.

Twin screw extruders process flame retardant masterbatch, filled masterbatch, masterbatch, biaxially oriented film, flame retardant sheet, automobile compounding, thermoplastic elastomers, rubber & plastics blending, etc.

Modification and pelletizing of general purpose plastics

Reinforcement and flame retardant of engineering plastics: compounding PP/PE with calcium or talc mineral fillers.

Rubber and Plastic blending (PS+SBS, PA+EPDM, PP+NBR, EVA+ Silica Rubber)

Alloying Plastic (PC+ABS, PA+ABS, CPE+ABS, PP+EPMD, PA+EPMD, PP+SBS)

Bio Polymers

Grafting and Cross-link material ( PE crossing-link cable and pipe )

Thermoplastic elastomer ( TPE , TPU )

Coloring of plastics

Nano masterbatch

Anti-bacterial, anti-fog, bio-degradable, electric masterbatch

Concentrated masterbatch

Masterbatch special for BOPP

Ultra-high-molecular-weight polyethylene (UHMWPE) special for piping

Extruder OEM makes:

APV, Buss, Clextral, Coperion, CPM(Century Extrusion), Entek, Farrel, JSW, SM Platek, Berstorff, Kobe, Kobelco, Leistriz, Maris, Steer, Theysohn, Toshiba, Werner & Pfleiderer, Xtrutech, Feddem, Zeppelin, etc.

Chinese OEM makes:

Keya, Ruiya, Useon, Meizlon, Nanjing Guangda, Tengda, Jieya, Haisi, Kairong, Juli, Kerke, Cowin, Cenmen, Chuangbo, Dart, Dema, GS-Mach, Hone, Hengao, Giant, Jinji, Jinwo, Onplas, Sunmac, Yongjie, etc.

Material options:

Nitriding Steel: GB 38CrMoAlA, DIN 1.8509, 41CrAlMo7, JIS SACM645, EN41B, SAE 4140HT, SAE 8550, etc.

Tool Steel: GB W6Mo5Cr4V2, AISI M2, DIN 1.3343, JIS SKH51, AISI D-2, SAE H-13, etc.

PM HIP: GB WR5, WR13, WR14, CPM10V, CPM9V, X235, X245, etc.

Stainless Steel: SAE 316L, 440C, etc.

Special alloys: Hastelloy C-276, etc.

Applications: high filler and color masterbatch compounding(CaCO3, TiO2, carbon black, talc, color pigments, etc.)

Petfood, aquafeed, human food, pulp & paper, etc.

Plastics: Masterbatch, Color Concentrate, Filled Thermoplastics, BMC, Reinforced Thermoplastics, TPE, Silicone, Silicone Compounds, Fiber Reinforced Compounds, Hot Melt Adhesives, Powder Coating.

Consumer Products: Adhesives, Sealants, Mastics, Putties, Soaps, Detergents, Toner

Keywords: extrusión doble husillo paralelo corrotante, cámaras de extrusión doble husillo paralelo, husillos de extrusión paralelos