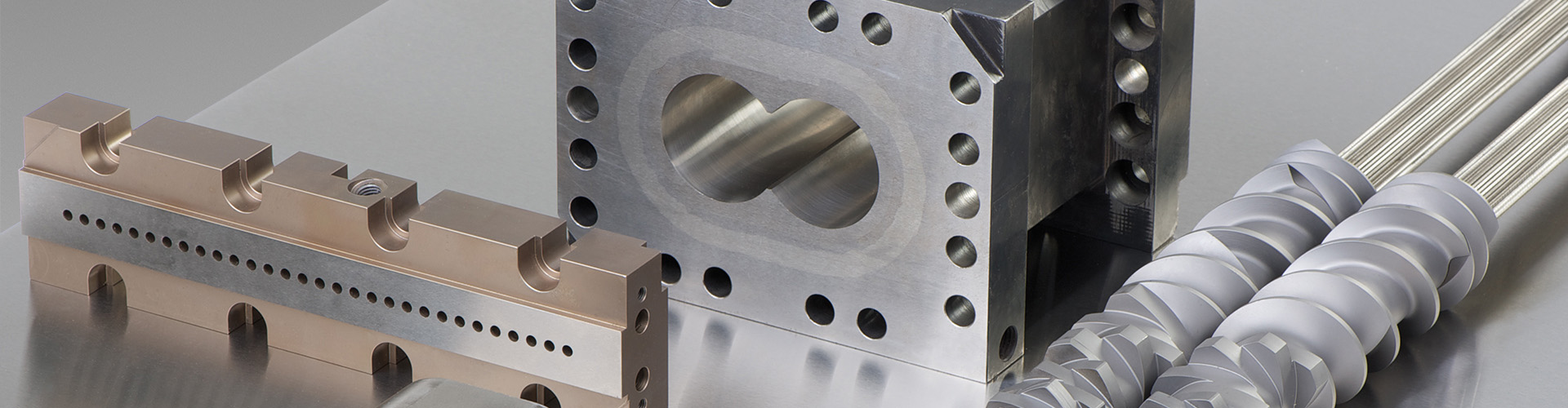

The most important components in all twin screw extruders are the barrel and screw assemblies. The quality and finish are carefully matched to the complex interaction of barrel, screw and raw material. Extruder barrels are hardened alloy steel or contain bimetallic cast liners to add wear and chemical resistance. The barrel end sections are equipped with a rupture disc port to protect against excessive pressure buildup. These features ensure consistent quality of the final product as well as extend the service life of the equipment.

Barrel venting

The co-rotating twin screw extrusion system provides that screw channels in the venting area are only partially filled with material. This permits efficient single-stage or multi-stage venting. A vacuum system with separator is installed on the extruder frame, and, like all serviced elements, it is easily accessible.

Vent Barrel Sections

For vacuum and atmospheric venting to remove moisture, solvents, and other volatile substances.

Feed Barrel Sections

Enable multiple feeding of dry ingredients and injection of liquid materials.

Combination Barrel Sections

Introduce materials downstream of the main feed point with the use of a side feeder. The combination barrel top port may also be used for venting.

A variety of materials, metal treatments and special wear resistant liners are available to provide wear and corrosion resistance for specific applications.

Products

Segmented Barrels

modular twin barrel for twin screw extruders

Hemu Precision Machinery Co., Ltd. © 2021